Hanford Mills Museum

Hanford Mills Museum

Hanford Mills Museum

Hanford Mills Museum

|

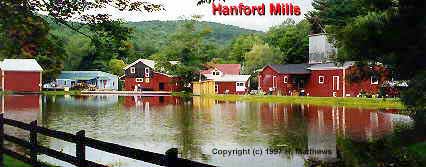

Come see history at work. Watch a water wheel at work and experience one of the area's oldest historic, operational sawmill, gristmill, and woodworking shops! The Hanford Mills Museum, County Routes 10 & 12, East Meredith, NY 13757 (607)278-5744  The complex of weathered wood buildings reflected in the mill pond mirrors more than 150 years of rural life and industry in the northwestern Catskill Mountains. From its start as a sawmill in the 1840s to its closing in 1967, the sawmill supplied generations with the materials they needed to build their homes and run their farms.

If you like old mills and antique industrial equipment installations then this is the place to go. We saw more line shafts and pulleys at work here than ANY other place we've been. As a part of the Antique Engine Jamboree, tours were given through the whole museum and this included the tour of the "basement" where there were more shafts, gears and pulleys than you can count. The 1926 Fitz water wheel was turned on for us as we stood over the spillway and watched the wooden gearworks begin to turn. Later, we went into a storage area where there was a shelving rack of wooden pulleys of enormous sizes and quantities and I learned what a pillow block is. Back up topside, we were treated to a demonstration of making a wooden barrel top and shown the rest of the operations. Other functions included broom handles, milk crates and butter tub covers. It's a functioning woodworking factory where wood products continue to be made on water-powered machinery in an authentic nineteenth century setting. Water was the first source of power for the mill, dating from 1820, but other power came into being later on. John Fitz, 1847-1914, inventor and manufacturer of the "modern" Steel Overshoot Water Wheel is pictured at the left. The Fitz Steel Overshoot Water Wheel is the product of three generations of unbroken experience in the design and manufacture of water wheels. Its high efficiency is due to its correct mechanical principles and to its careful design and construction. The manufacture of Overshoot Water Wheels was begun by Samuel Fitz, in Hanover, Pa. in 1840. The industry had been carried on continuously since that time on the same site under the management of the son and grandson of the original founder. The earlier Fitz Wheels were, of course, built of wood, but the greater part of the business is the manufacture of the all-steel Overshoot Water Wheels. A horse-power is the amount of power required to raise 33,000 pounds one foot per minute. To compute the horse-power of any stream, multiply the number of cubic feet of water it flows per minute by 62-1/8 (which is the weight in pounds of one cubic foot.) Multiply that product by the head (in feet) and divide the product by 33,000. The quotient will be the full horsepower of the stream. Most turbine manufacturers claim that their wheels will develop 80% efficiency, but it is well known that very few of them in actual use will ever reach 70% efficiency, and then only under the most favorable conditions. The Fitz will develop from 90% to 95% efficiency, depending upon the diameter of the wheel, or at least one-third more power than any other wheel using the same amount of water. The EFFICIENCY of a water wheel is the actual horse-power which it develops with a certain amount of water as compared with the power which it is theoretically possible to develop with that amount of water. It is impossible to develop the full theoretical power, for there must always be some loss, but the nearer the wheel approaches this performance, the higher the efficiency. BACK-WATER occurs when the tail race from the mill becomed clogged or choked so that the wheel has to wade in the water it discharges. The greatest care should be exercised to avoid this condition. The JACKSHAFT is the shaft which carries the pinion wheel which gears into the segment gear, or master wheel. A PINION is a small gear wheel which gears into a larger one. The MAIN DRIVE PULLEY is the large pulley or belt wheel that usually goes on the jack shaft and carries the belt that drives the line shaft to proper speed. The CHUTE is the short trough of wood or iron which conveys the water from the gate to the buckets of the water wheel. It is generally about three feet long.

An operating 1908 Fairbanks Morse gas engine is belt coupled to a dynamo, which made DC power to light the mill as well as the town. There is also a large steam engine set in place, but it needs much restoration work. Jane McCone (jmccone@catskill.net) writes to tell us that Hanford Mills Museum will be re-installing steam power in the old mill beginning in January 2000. A new boiler will be built and the search is on for the right engine. The mill will run on water power in the mornings and steam in the afternoons. We came here for an engine show, but we were treated to an EXCELLENT museum tour as well! The Engine Jamboree features antique engines, tractors, automobiles, fire trucks and boats. The Fall Harvest Festival features corn harvesting, draft horses, mill demonstrations, food and much more. |

Please visit our sponsors on the Business Card Page

There's a WHOLE LOT more to this site so click and cruise around!

![]()

| ENGINES | SHOWS | SEARCH | SUPPLIERS | IGNITIONS | ABRASIVES | CLASSIFIEDS | BOOKS |

Published by Harry F. Matthews © 1995 - 2000. ALL RIGHTS RESERVED!